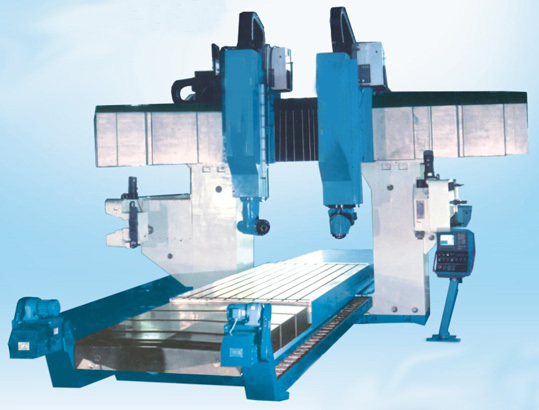

DOUBLE SPINDLE PLANER-TYPE MACHINING CENTER

DOUBLE SPINDLE PLANER-TYPE MACHINING CENTER

DOUBLE SPINDLE PLANER-TYPE MACHINING CENTER

- Detail

- Parameters

This machine is a CNC planner-type machining center with fixed cross-rail and column. The machine which is equipped with double ram and tool, and advanced automatic universal milling head can mill, bore, and ream pentahedron of workpiece at all directions during once clamping. It is controlled for 7 axes and simultaneous control of 3 axes. It is widely used in manufacturing industries such as aircraft, mould, automobile, and etc.

●Reasonable and advanced design, and beautiful configuration. Cross guideway adopts combined structure of double liner guideway and slide guideway. Up and down guideway with large combined length, large parts with enough gibs, high machine rigidity and large bearing capacity.

●CNC system and AC Servo motors: Siemens (Germany), Fanuc (Japan), Fagor ( Spain) or Fidia ( Italy).

●C axis on automatic universal milling head can rotate ±370° and 45° axis can automatically swivel locate for vertical and horizontal exchange.

●Equipped with chain-type tool capacity for automatic exchanging tools.

●The spindle realizes the automatic infinitely variable speed by the way of AC servo motor in combination with mechanical gearbox.

●With tool self-lock.

●Automatic central lubrication with fixed time and quantity.

●Equipped with enclosed hood.

●With automatic chip conveyer.

●The vertical travel of ram (800, 1000, 1250, 1500, 2000) mm is optional.