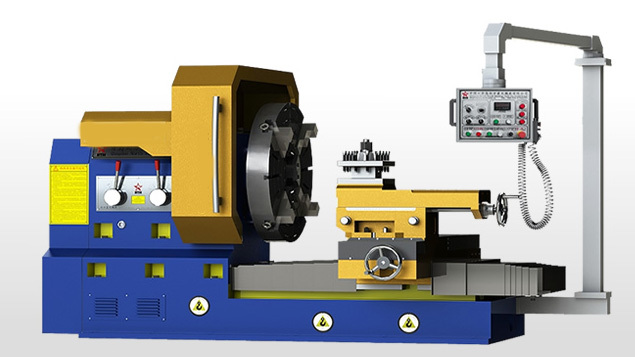

End Face Lathe CX64125

End Face Lathe CX64125

End Face Lathe CX64125

- Detail

- Parameters

Conventional End Face Lathe, The machine spindle adopts double-rows roller bearings, which makes the spindle has high rigidity and accuracy. The spindle speed is driven by the AC frequency motre and servo motor to realize stepless speed regulation with large transmission torque. The machine bed guide rails adopt dual/triple rectangle structures with big spacing distance and high rigidity, which is specially used for low speed heavy duty cuttings. Batch-type centralization lubrication make the machine maintenance more easier.

This lathe adopts mechanical-electrical integration design with perfect flexbility used for turning various tyre mold, large disc part, ring part, etc.Besides, it can realize different machining processes like inner hole, outer circle, end face, conical surface, circular arc surface and threading. It is an ideal equipment for machining various tyre mold, large flat disc part, ring part.

| CX64 Conventional Facing Lathe | |||||||

| Model | Unit | CX64125 | CX64160 | CX64200 | CX64250 | CX64300 | |

| Machining Technical Parameters | Max.swing diameter over machine bed | mm | 1250 | 1600 | 2000 | 2500 | 3000 |

| Max.swing diameter over cutting tool carriage | mm | 800 | 1250 | 1600 | 2000 | 2500 | |

| Max.work-piece weight | T | 2T | 3T | ||||

| Max.work-piece length | mm | 500 | 750 | ||||

| Machine Bed Parameters | Guide rail type | Stepless variable frequency | |||||

| Guide rail width | r/min | 6-210 | 5-140 | 4-106 | 2-70 | ||

| Headstock | Spindle speed | KW | 15 | 22 | 30 | ||

| Spindle speed range | mm | 1000 | 1250 | 1600 | 2000 | 2500 | |

| Main motor power | knm | 20 | 40 | ||||

| Max.X Axis stroke | mm | 625 | 800 | 1000 | 1250 | 1500 | |

| Max.Z Axis stroke | mm | 500 | 750 | 1000 | |||

| Feed Data | Feed range of X Axis | mm/min | 1-200 | ||||

| Feed range of Z Axis | mm/min | 1-200 | |||||

| Rapid moving range of X Axis | mm/min | 2000 | |||||

| Rapid moving range of Z Axis | mm/min | 1500 | |||||

| Other Data | Machine Length | mm | 3000 | 3500 | 3500 | 4500 | 4500 |

| Machine Width | mm | 2000 | 2500 | 2800 | 3200 | 3500 | |

| Machine Height | mm | 1500 | 1800 | 2000 | 2500 | 3000 | |

| Control System | Semi-automatic | ||||||